China Wholesale Bearing Cover Cap Suppliers – Cast iron reducer housing – Zhengheng

China Wholesale Bearing Cover Cap Suppliers – Cast iron reducer housing – Zhengheng Detail:

reducer housing sand molding material

Sand casting

Furan resin

Casting sulfonic acid curing agent

Furan film removal agent

Silane

Sand mold coating

Molten iron for reducer housing casting

Pig iron

Scrap

Ferrosilicon

Ferromanganese

Pyrite

Electrolytic copper

Silicon carbide

Ferrochrome

Tin

Recarburizer

Inoculant

Reducer housing after casting process material

Steel shot

Ceramic grinding wheel

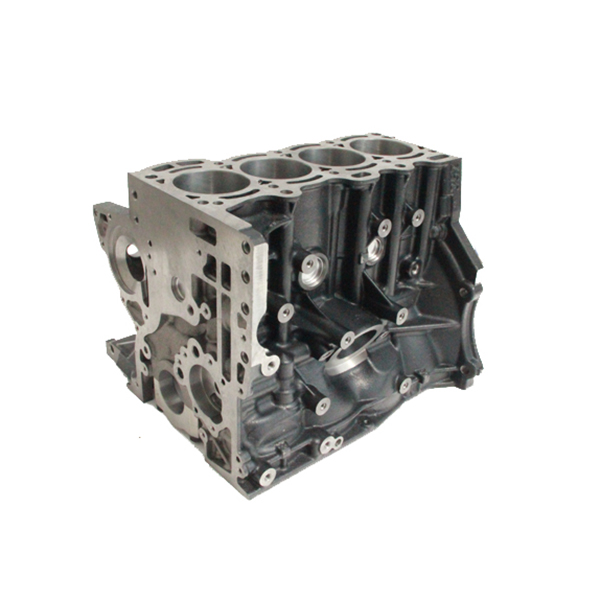

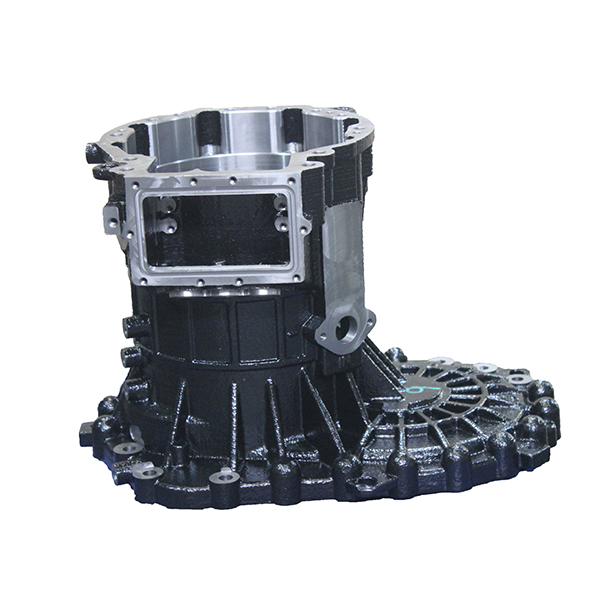

Product material: QT600

Product weight: 31.52KG

Product size: 380*400*270.5

Constant power production of the cast iron reducer shell for the Great Wall pickup new energy vehicles, reducer shell in the design of the reducer shell and cover, the requirements to meet the premise of strength, steel, but also to consider its compact structure, convenient casting, light weight and the use of the requirements. Because the reducer shell and shell cover are the most complex parts in the reducer structure. The bearing span of the shaft arranged on the widened bearing seat is shortened by setting a widened bearing seat on the shell, so as to effectively improve the strength and stability of the shaft in the process of operation. The reducer shell and shell cover are mostly cast iron.

We are a professional manufacturer of reducer housing from China, wholesale quality products, according to the engine cylinder block drawing co-research and development and manufacturing, we have professional technical team support and perfect after-sales service. Look forward to working with you!

1. We focus on reducer housing and all kinds of cast iron, cast aluminum parts, with years of research and development experience and industry accumulation.

2. We have successfully cooperated with many enterprises around the world, and have professional sales personnel in various languages.

3. Focus on OEM customization, you can get good quality and the most competitive price from us.

4. Passed the international advanced IATF 16949 system certification, standardized production.

5. Coordinated development, from casting to machining to provide strong technical support, customer new product development success rate reached 100%.

6. At the same time, we have a casting factory and a machine processing factory, providing one-stop finished products from mold, casting and processing.

Packing details:

1. Original packaging: 1PC/piece, 20 pieces/box (the quantity depends on the product); Plastic packing + export laminate box

2. Special packaging: can be customized, warmly welcome to contact us for more details.

Transportation:

1. Standard export packaging, strong packaging to ensure long shipping and international express.

2. We have professional staff to prepare the goods, pack and pack to ensure punctual delivery and strong packing.

3. Customers can choose their own ship agency or our long-term cooperation ship agency.

1. Gear reducer housing spot: If there is inventory, generally 15-20 days after receiving the payment can be delivered.

2.OEM products: delivery will be arranged within 30-65 days after receipt of formal drawings. (Depending on the specific product)

1. Accept OEM manufacturing

2. Deliver the goods to our customers quickly and accurately.

3. Professional technical team and strict quality control system, to ensure that the best parts to your hands.

4. One-stop procurement of cast iron parts, cast aluminum parts and reducer housing to help you reduce the purchase cost of parts.

1. Q: Can I add my logo on the product?

Yes, welcome custom logo, OEM production.

2. Q: Can you use our drawings to develop parts?

Yes, please provide drawings with technical requirements to protect intellectual property rights.

3. Q: Do I need to pay the mold fee again next time I order?

A: It is not used within the mold life. After the mold life expires, it can be negotiated according to the demand.

4. Q: What are your payment terms?

A: T/T 50% deposit, 50% before shipment. We will send you pictures of the fully packed goods before shipment

5. Q: How do you make our business a long-term good relationship?

Answer: 1. We maintain good quality and competitive prices to ensure that our customers benefit;

2. We respect every customer and regard them as our friends. We sincerely do business with them and make friends no matter where they come from.

Product detail pictures:

Related Product Guide:

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for China Wholesale Bearing Cover Cap Suppliers – Cast iron reducer housing – Zhengheng , The product will supply to all over the world, such as: Macedonia, Tajikistan, panama, With the technology as the core, develop and produce high-quality merchandise according to the diverse needs of the market. With this concept,the company will continue to develop merchandise with high added values and continuously improve items,and will present many customers with the best goods and services!

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.